|

Mining of slate

Many dimension stones like granite or marble are mined in form of blocks for own further manufacturing or to sell it to other companies. Roofing slate is commonly exploited and manufactured by the same company. The production of roofing slate demands specific knowledge and experience to guarantee a constant quality.

Nowadays, slate is mostly exploited in open pit quarries but there has been a long period of underground mining, for example, in Germany, France or Belgium. Mining in Spain is currently in a kind of stage of transition from open pit quarrying to underground mining.

Assuming a fairly simple geological setting and a stable rock mass, underground mining can be an economic and efficient alternative to open pit quarries.

Thus, one has to take into account the various circumstances and conditions to start an operation and to keep it economically efficient.

Besides external factors like the market if running a slate mine and -production several topics have to be considered to ensure economic mining, depending on the specific local situation. One can roughly distinguish between a mining plan described and the design of the production.

In open pit quarries slate is extracted from the surface mostly working from several benches. In the past, slate blocks were gained by using blasting but today slate blocks are mostly extracted by diamond wires or disc saws always under wet conditions. Cuts by diamond wire are made perpendicular to the direction of the cleavage plane. Normally the blocks are firstly separated by a wheel loader which can be supported by a pneumatic jackhammer.

Today, underground mining is carried out in a room and pillar system. As in open pit quarries slate blocks are either extracted by diamond wires or disc saws under wet conditions.

Pictures

Please move your mouse over thumbs to enlarge photographs

-

Fig. 1: Drift in an underground mine (Germany). A drift is a "tunnel" wich lead to the different rooms where slate is mined.

-

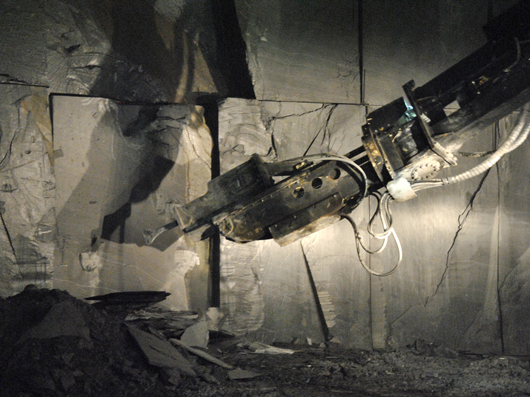

Fig. 2: After sewing, large slate blocks are gained by a pneumatic chisel

-

Fig. 3: A pillar between two rooms which show the former mining progress.

-

Fig. 4: Access to an underground mine (Liguria, Italy). The yellow "tubes" are for the weathering of the mine.

-

Fig. 5: Room-pillar mine in Liguria (Italy).

-

Fig. 6: Opening of a new room in the underground mine "Pussui" (Liguria, Italy)

-

Fig. 7: A surprisingly little saw during the opening of a new room in the underground mine "Pussui" (Liguria, Italy)

-

Fig. 8: The gained slate blocks are covered by a foil to maintain the natural moisture which is necessary for the splitting (underground mine "Pussui", Liguria, Italy). I know this covering only from Liguria.

-

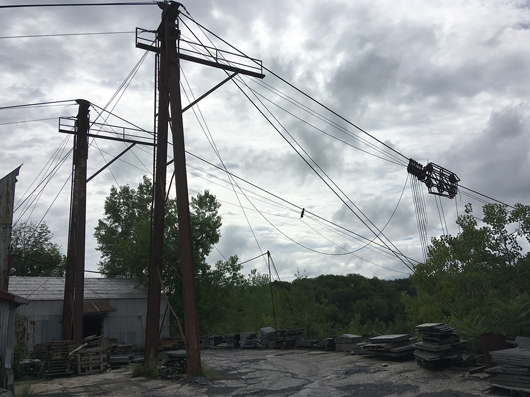

Fig. 9: Derricks and carriers to hoist slate blocks in the slate quarry at Pen Argyl (north of Slateville, Pennsylvania, USA).

-

Fig. 10: Derricks and carriers to hoist slate blocks in the slate quarry at Pen Argyl (Pen Argyl, Pennsylvania, USA). Its a kind of an open shaft with an actual depth of about 150 m (500 feet).

-

Fig. 11: Slate quarry north of Slateville (Pennsylvania, USA)

-

Fig. 12: Slate quarry in Herbeumont (Ardennes, Belgium)

-

Fig. 13: Slate quarry "Oertelsbruch" in Thuringia (Germany).

-

Fig. 14: Slate quarry in Galicia (NW-Spain)

-

Fig. 15: Slate quarry in Galicia (NW-Spain)

|